No products in the cart.

MASTERCLASS – AIR CONDITIONING TECHNOLOGY

In last month’s article (VOL 51) we looked at the Airside control Fan Coil Unit based system

We now continue in more detail with these important criteria in mind in our coverage of this increasingly popular and important approach to comfort conditioning.

Airside/Waterside Control Fan Coil Units

In last months article we briefly explained the operation of Airside control fan coil units. In this months article we tackle Waterside control, as well as the advantages and disadvantages of Airside over Waterside control fan coil units.

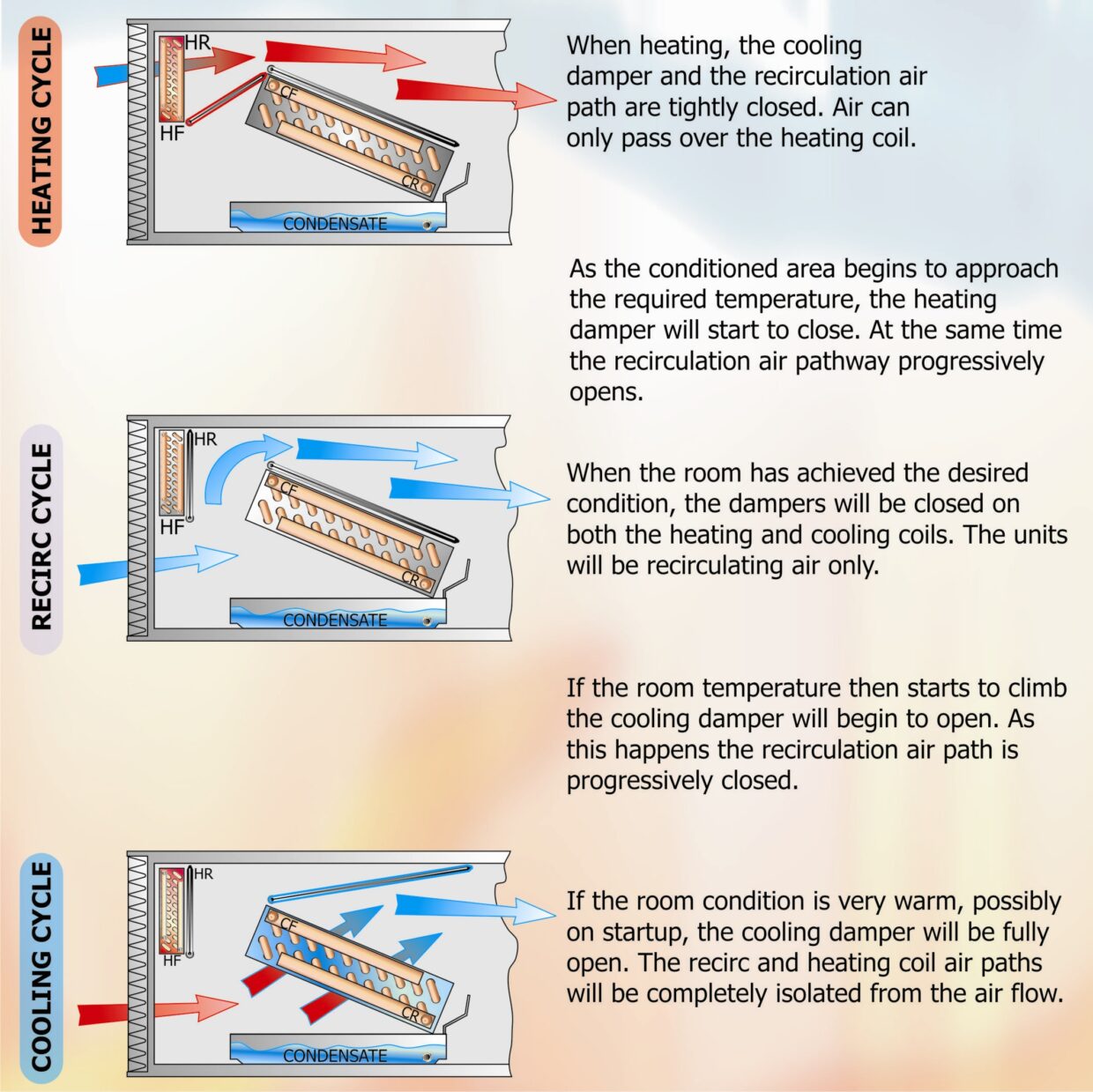

The following stages describe and illustrate the cooling, bypass (ventilation only) and heating operations of Waterside control more clearly:

Heating Mode:

Waterside – Cooling valve in bypass mode, Heating valve in the open / control mode thus allowing low-pressure hot water to pass through the heating coil and affect heating.

Bypass Mode:

Waterside – Both cooling and Heating valves in their bypass positions. Therefore neither coil is in circulation.

Cooling Mode:

Waterside – Cooling valve in open / control mode thereby allowing Chilled water to pass through the cooling coil and affect cooling. Heating valve in bypass mode,

Comparison of Advantages and Disadvantages

When compared to its’ Waterside counterpart, Airside control fan coil equipment is claimed to be more efficient. This is due to the Airside control fan coil equipment being more effective in its thermal control operation because the unit maintains the space condition by mixing quantities of heated or cooled air with a proportion of re-circulated air. As stated earlier, the controls can respond very quickly and accurately to changes in space temperature.

VOL 52 Airside/waterside control fan coil units – Heating Dampers

Waterside control units, on the other hand, are less responsive due to the fact that they rely on the control, to valve, response time. The unit output not only being related to the temperature of the space but also the condition and rate of the chilled water subsequently being supplied (following valve initiation), thereby, possibly operating with a certain degree of lag. For instance, when a waterside unit changes over from Heating to Cooling, the unit has to dissipate all the heat remaining in the Heating Coil before it can commence the Cooling operation (and vice versa for the changeover from Cooling to Heating).

Airside control fan coil equipment is also potentially easier to install and commission. With this type of system the water flow is allowed to circulate relatively unrestricted with the airside mechanism, factory pre set, operating and modulating to maintain the space temperature. This is contrary to the Waterside system that requires proper and accurate balancing in order for the 4 port valves to control the system correctly

Airside control systems shouldn’t suffer from a water-related problem. Waterside control units utilise a valve to control the flow of water through a small clearance section within the valve. This section can be prone to blockage or sticking, when the water system concerned has not been thoroughly and frequently maintained, there by rendering the system or unit out of design parameters.

The Airside control system has no requirement for 4 port valves. This means that the overall system has a reduced resistance requirement, which in turn gives savings on the pump or pumps due to a lower duty being necessary.

It is simple to use, service and maintain and can be manually set up should the electrically operated controls fail.

Airside control systems have, of late, been the subject of various in-depth investigations and reviews with regard to net performance. Prospective users of this type of system must ensure that they have been soundly advised on the available capacity within the space to be conditioned.

However, Airside control systems can, in some instances, be unsuitable in certain applications due to physical space restrictions. Unfortunately, because of the area required to occupy and operate the damper mechanism, the unit can be larger than usual, particularly with the vertical style unit, and this may prohibit it’s use for instance under a particular sill height.

Summary

Like all forms of heating, ventilation and air-conditioning equipment used in today’s building services environment, the Airside Control Fan Coil Unit has its place for applications within the range of solutions for heating and cooling problems.

As can be seen from the above descriptive passages, this type of equipment can offer benefits in both the initial capital cost of design, application, installation and the ongoing expenditure relative to efficiencies in some areas. However, it can lose out in not being able to fit some installation situations and the efficiency can be called into question if the initial equipment design hasn’t been 100% or the net output hasn’t been clearly stated and taken into consideration.

DISCLAIMER:

Whilst every effort is made to ensure absolute accuracy, Business Edge Ltd. will not accept any responsibility or liability for direct or indirect losses arising from the use of the data contained in this series of articles.