No products in the cart.

In days gone by when men were men and computers were the size of houses there was a very definite need for precise air conditioning systems. Close control air conditioning was developed to maintain constant temperatures within 1°K in environments containing sensitive computer equipment. The early to mid seventies saw an explosion in the number of companies using computers in their everyday business activities. Vast banks of computer equipment were housed in purpose built IT rooms which required close control air conditioning to maintain temperature and humidity within these tight parameters.

The IT market proved lucrative for many close control manufacturers as more and more companies invested in bespoke IT rooms and this continued until the advent of the personal computer in the late eighties. Technology now allowed for individuals to have their own desktop computer within the office area. This modern form of computer no longer required the exact temperature controls of its predecessors and its new office environment was within the jurisdiction of comfort air conditioners employed to manage the temperature of the office space. This was of course the primary reason for the massive down-turn in close control equipment sales and the upsurge in unitary equipment installations based on low/high wall mounted products and ceiling cassettes.

During the mid-nineties a new market for close control opened up with the explosion of the Internet. Large purpose built rooms containing huge servers needed to service the demand for Internet access began to emerge and these environments required close control air conditioning. Another area which had developed in parallel with the IT market was that of telecommunications. The fragmentation of the telecommunications industry created a huge demand for close control products for the growing number of digital exchanges coming on line.

The revival of close control air conditioning brought with it the modern day demands of energy conscious, environmentally aware customers. With the introduction of this more sophisticated market, close control systems have had to offer more product benefits than ever before.

What is Free Cooling?

Free Cooling utilises ambient air, when at sufficiently low temperatures, to chill one of the following:

- The supply air to the conditioned room, by directly injecting the appropriate volume of fresh ambient air into the room, normally through the close control air conditioning unit.

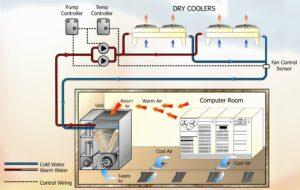

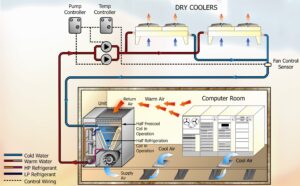

- A water / glycol mixture that is passed through an externally mounted Dry Air Cooler to remove heat energy, the cooled fluid then being recirculated through a Free Cooling Coil mounted within the close control air conditioning unit.

These techniques can either eliminate the need for mechanical cooling which requires one or more DX System Compressors to run, or will at the very least, reduce the running time and the cooling load that would otherwise be handled entirely by mechanical cooling. The benefits of this are explained below.

Minimum mechanical cooling drastically lowers the energy consumption of the air conditioning system, reducing running costs and also minimising environmental impact. If the capital cost of such systems turns out to be higher, this additional expenditure is often recouped within a short space of time, after which the cost savings become dramatic.

Free Cooling Potential

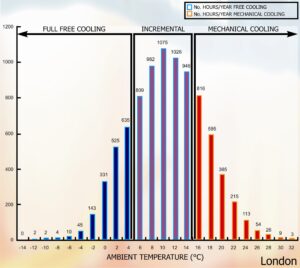

Graph 1 shows the number of annual hours for London relative to Ambient Dry Bulb Temperature. The Graph also show the annual hours available for Free Cooling, Incremental Cooling and Mechanical Cooling, the breakdown of which is as follows:

| Hours/Annum | % | |

| Free Cooling | 1701 | 19.4 |

| Incremental Cooling | 4838 | 55.4 |

| Mechanical Cooling | 2197 | 25.2 |

| 8736 |

The different methods of achieving free-cooling can be broken down into three categories: which we will look over in the next couple of Masterclass articles.

Full Free Cooling

Full Free Cooling

Full Free Cooling is always available at ambient temperatures of 5°C and lower to satisfy the cooling duty. It is also possible to obtain the full Free Cooling effect at external ambient temperatures higher than 5°C when only partial load is experienced, as is often the case during the winter months. In the full Free Cooling mode, the fluid circulation pump operates, circulating a cold water/glycol solution through the Free Cooling coil where room heat is removed and returned to the dry coolers for rejection to atmosphere. None of the compressors run in this operating mode.

At medium range ambient temperatures, a useful measure of partial Free Cooling is available. At these conditions, the pump will circulate a water/glycol solution through certain sections of the Free Cooling coil and then one or more mechanical cooling refrigeration circuits will provide the required additional cooling.

Incremental Free Cooling

DISCLAIMER: Whilst every effort is made to ensure absolute accuracy, Business Edge Ltd. will not accept any responsibility or liability for direct or indirect losses arising from the use of the data contained in this series of articles.