No products in the cart.

Vol 12 Fundamentals – Part 12 Expansion Devices (Continued)

Vol.12 Expansion Devices (Continued)

Author Mike Creamer, Business Edge Ltd

AIR CONDITIONING TECHNOLOGY – PART 12

In Vol 11 article we completed our review of Thermostatic Expansion Valves (Internally and Externally Equalised). The following completes our study of expansion devices.

HAND OPERATED EXPANSION VALVE

This type of expansion valve is simply a hand-operated needle valve. The valves are normally dedicated to large capacity systems with a fixed or very stable thermal load since any change required in refrigerant flow must be achieved by manually adjusting the valve setting. This clearly requires constant attendance by an engineer.

The liquid refrigerant flow across the valve is purely dependant upon the difference between the entering pressure (high pressure from the condenser / receiver) and the pressure at the outlet of the valve (low pressure within the evaporator), coupled with the degree of needle / orifice opening. This type of valve is unable to provide any real degree of variation in refrigerant liquid flow to suit variations in evaporator load and cannot automatically protect the compressor against excessive liquid flooding.

The Hand Operated Expansion Valve must also be closed when the compressor is stopped to prevent liquid flooding of the compressor since liquid refrigerant will continue to flow through the evaporator until system pressures have equalised. If the evaporator fan has also been stopped, there will be no thermal load to continue the evaporation of this liquid.

A Hand Operated Expansion Valve is often used to regulate the flow of oil from an oil separator back to the compressor crankcase and can also be used in Low Pressure Float Control Systems.

AUTOMATIC EXPANSION VALVE (CONSTANT PRESSURE)

This type of valve regulates the flow of liquid refrigerant to maintain a constant evaporating pressure and temperature. The valve has an adjustable spring pressure to allow the desired evaporating pressure to be set.

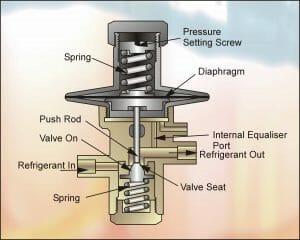

A schematic illustration of the valve is shown in Figure 1.

FIGURE 1

A constant evaporating pressure within the evaporator is achieved by increasing or decreasing the amount of refrigerant within the evaporator. If the evaporator pressure falls due to decreasing load, the spring overcomes the pressure under the bellows and forces the valve to increase the refrigerant flow. The increased flooding of the evaporator leads to more evaporation of liquid, which increases the evaporator pressure until the pressure below the bellows is in equilibrium with the spring pressure above.

When the evaporator pressure rises due to increasing load, the spring pressure is partially overcome and the needle valve starts to close. The reduction in liquid refrigerant within the evaporator results in reduces evaporation and a subsequent drop in evaporator pressure until equilibrium with the spring pressure is attained.

Unfortunately, this type of refrigerant flow control causes the evaporator to be short of refrigerant when the thermal load is high as only a small quantity of liquid needs to be present to produce the required evaporating pressure. The remainder of the evaporator is under utilised and could give rise to excessive superheat with detrimental effects on compressor motor windings. As the thermal load diminishes, the evaporator is filled with an increasing amount of liquid refrigerant in an attempt to bring the evaporating pressure up to the required setting by exposing more evaporator surface area to liquid refrigerant. Should the load fall to a very low level, evaporator flooding may occur leading to compressor damage, particularly if the system is over-charged with refrigerant.

The Hand Operated Expansion Valve results in poor system efficiency and is therefore not very often used in commercial systems. When the thermal load is high, the liquid refrigerant quantity in the evaporator is low. Since the valve will have been set for a desired evaporating temperature, this will remain constant irrespective of system load. If the evaporator pressure were allowed to rise with an increase in thermal load, as with other types of refrigerant flow controls, the compressor efficiency would be greater due to higher suction pressure.

The constant evaporating temperature characteristic of this type of valve make it useful for small refrigerators and low temperature storage cabinets. The Automatic Expansion Valve can also be applied where the evaporating temperature must run close to 0.0 Deg C without freezing.

The Hand Operated Expansion Valve always closes fully when the compressor is stopped as refrigerant liquid in he evaporator continues to vaporise with an attendant increase in pressure. This ultimately overcomes the spring pressure causing the needle valve to close. When the compressor is started, the suction and evaporating pressure fall until the spring pressure open the needle valve at the desired pressure setting.

ELECTRONIC EXPANSION VALVE

The application of electronics to refrigeration and air conditioning systems has brought tremendous benefits to these industries offering a finer degree of control and system protection. The Electronic Expansion Valve provides the following benefits:

1 Precision refrigerant flow control using PI (Proportional-Integral) control algorithms.

2 Compensation for changes in liquid sub-cooling ahead of the expansion valve.

3 Rapid response to sudden and substantial changes in thermal load.

4 Low superheat levels allow greater utilisation of evaporator coil leading to maximum efficiency whilst maintaining adequate protection for compressor motor cooling.

5 Electrical connection between the key components offers greater flexibility with regard to positioning.

Many electronic expansion valves utilise a modulating voltage signal from a controller to an actuator, which in turn controls the valve. As the supply voltage is increased, the pressure in the actuators container in increased and the increased valve opening permits greater refrigerant flow. Fine control results and the valve close completely when the control voltage is removed.

Technology now available permits the valve to precisely controlled by PWM (Pulse Width Modulation). Over a period of 6 seconds, a signal is transmitted from the controller to the valve coil. This causes the valve to open and then close allowing a given amount of liquid refrigerant / saturated flash gas to pass into the evaporator and it is the relationship between the opening and closing times that determines the capacity of the valve. At high thermal load, the valve will remain open for most of the 6-second period and at low load, the valve will remain closed for the major part of the 6-second cycle. When no refrigeration is required, the valve will shut altogether and act as a liquid line solenoid valve.

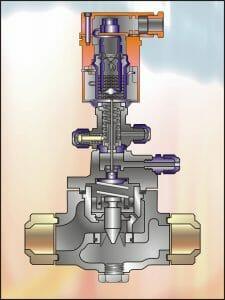

Figures 2 & 3 show the Electronic Expansion Valve manufactured by Danfoss.

FIGURES 2 & 3

FIGURE 4