No products in the cart.

Vol.1 AIR CONDITIONING TECHNOLOGY

Author Mike Creamer, Business Edge Ltd

Hg mercury – Heavy silver-white metallic element. Only metal that is liquid at room temperature. Symbol = Hg. Freezing Point = -40 Deg C.

This series of articles will cover the fundamental principles of comfort and close control air conditioning, applications, design, equipment, components and systems. It is intended that the articles be used as an ongoing source of technical reference for experienced personnel as well as newcomers to our industry. Several equipment manufacturers have agreed to support the series with technical data on their products and the writer welcomes approaches and contributions from other interested parties. The work may ultimately be published in book form and will also cover refrigeration.

PART 1

WHAT IS AIR CONDITIONING?

Full air conditioning implies the control of temperature and humidity levels within a conditioned space. Control of pressure is occasionally required for special applications. Air conditioning equipment will always include the ability to reduce the temperature and humidity level of the air being processed. Most equipment will offer the option of heating to raise air temperature and more specialised equipment has an optional humidification facility to raise air humidity levels. Air conditioning also includes the control of motion of the air and the regulation of purity levels.

The above can be summarised as follows:

- Temperature – Air temperature is controlled by the removal (cooling) or addition (heating) of sensible heat energy.

- Humidity – Air humidity level is determined by the moisture content. Air humidity is controlled by the removal (dehumidification) or addition (humidification) of latent heat energy.

- Purity – Air purity is a measure of cleanliness or air quality and is controlled by filtration and/or ventilation. Ventilation is the controlled introduction of outside (ambient) fresh air into the conditioned space to dilute the concentration level of contaminants.

- Motion – Motion or air movement covers the distribution and velocity of air introduced to the condition space. This is controlled by the air conditioning unit(s) or an air distribution system (ductwork and grilles).

- Sound – Sound or noise control may be required to attenuate (reduce) the noise generated by the air conditioning equipment and distribution system.

Air conditioning is normally applied to maintain the comfort and working efficiency of people or to manufacturing, industrial and scientific processes. The combination of the elements above has generated the term HVAC but an air conditioning system need not include all these elements.

For thousands of years mankind relied upon fires for heating and cool water for relief in high temperatures. The Romans conceived an effective form of radiant heating in certain buildings by circulating heated air through hollow walls and floors. In the warmer climates of the Middle and Far East, wet mats suspended in open doorways provided evaporative cooling. The incredible Leonardo da Vinci designed and built an enormous evaporative cooler in the fifteenth century. This machine consisted of a large drum rotated by water power (or by slaves when available!) which drew in air and supplied this to the conditioned space after washing and cooling the air inside the drum.

Only within the last hundred years has air conditioning become established and during this time the technology has developed to very advanced levels. Air conditioning is now a major industry throughout the World worth billions of pounds annually.

- Temperature – The temperature reading for air given by a normal thermometer or digital thermometer is defined as Dry Bulb Temperature (Deg C). The higher the sensible heat energy content of the air, the higher the Dry Bulb Temperature.

- Percentage Saturation – This is the ratio of the actual moisture content of the air in relation to the maximum moisture content the air could support at the same Dry Bulb Temperature. (Please note that the term Relative Humidity should not be used in this context).

Human Comfort

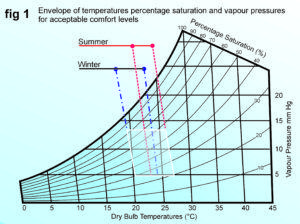

The objective of all comfort air conditioning installations and systems is to ensure the comfort of individuals in the conditioned zone and this is achieved by control of temperature and percentage saturation levels within prescribed limits. Following studies by ANSI & ASHRAE, * which measured the effects of temperature, humidity (percentage saturation), air motion and clothing on human comfort, the ANSI/ASHRAE Standard 55-1981 was developed. The results are very extensive but for our general purposes, the ideal comfort envelope is as defined in Figure 1.

Whilst internal design conditions must be based on the comfort requirements of the occupants, the energy consumption, equipment costs and other factors need to be considered. These factors will be covered later in the series.

* ANSI is the American National Standards Institute. ASHRAE is the American Society of Heating, Refrigeration and Air Conditioning Engineers.

FIGURE 1

BASIC DEFINITIONS & PRINCIPLES

Units – This series of articles is based purely on S.I. Units.

Mass – The Mass of an object is the quantity of matter it contains. Unit of measure: kg

Force – Force is the push or pull exerted by one body on another. Unit of measure: N (Newton)

Weight

The Weight of a body is equal to the force exerted upon it by the gravitational attraction of the Earth. At sea level, the Earth exerts a force of 9.81 N (Newtons) on each kgof matter. (N/kg).

Force and weight are in fact different although the unit kg is used for both.

Density & Specific Volume

Densityis the mass per unit volume of a substance and is expressed as kg/m3:

Mass (kg)

Density = ———

Volume (m3)

Specific Volumedefines the volume occupied per unit mass and is expressed as m3/kg:

Volume (m3)

Specific Volume = ———-

Mass (kg)

Density and Specific Volume vary with temperature and pressure.

Specific Gravity

TheSpecific Gravity (s.g.) is defined as the ratio of the weight of a substance in relation to the weight of an equal volume of water. As this is a ratio there are no units of expression.

Density (kg/m3)

Specific Gravity = ——————————

Density of Water (kg/m3)

Specific Gravitychanges with temperature. For non-scientific calculations this can usually be ignored. The Densityof water is 1000 kg/m3 (at 4 Deg C).

Pressure

Pressure is given by unit force divided by area and is normally expressed as N/m2.

Force (N)

Pressure = ————

Area (m2)

There are many units for the expression of Pressureand these include kN/m2,Paor kPa, mbaror barand of course, lb/in2. Numerous factors exist for conversion from one unit to another.

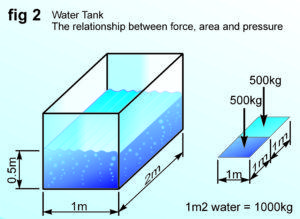

Example

Figure 2 shows a tank containing 1 m3of water weighing 1000 kg. The downward force due to gravity is equal to 9.81 N/kg. The total force exerted on the base of the tank is therefore 9810 N.

Force (N) 9810 N

Pressure = ———— = ——— = 4905 N/m2

Area (m2) 2 m2

Alternatively, this could be expressed as follows:

Force (N) 1000 kg

Pressure = ———— = ——— = 500 kg/m2

Area (m2) 2 m2

FIGURE 2

Atmospheric Pressure

Atmospheric Pressureis created by the gravitational force exerted upon the atmosphere throughout the full height of approximately 80 km (50 miles). This results in an atmospheric pressureat sea level of approximately 1.01325 bar (14.7 psi). Atmospheric pressuretherefore decreases with increasing altitude due to the reduced weight of air above the measured point.

Atmospheric Pressureis directly related to the Densityof the air and since this varies with temperature, Atmospheric Pressurealso varies. This is measured by a barometer to indicate imminent weather changes.

Absolute, Gauge & Vacuum Pressure

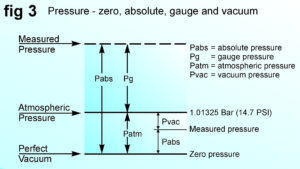

Absolute Pressure(Pabs) is the pressure exerted by a gas or a liquid above zero pressure. Zero pressureexists when a space is fully evacuated of any gas or liquid.

Gauge Pressure is measured by instruments that indicate a difference between the pressure of the atmosphere and the pressure of the gas or liquid. It is therefore necessary to add Atmospheric Pressureto gauge readings to establish Absolute Pressure.

Vacuum Pressure is measured by instruments that indicate the difference between Atmospheric Pressureand Zero pressure.

FIGURE 3

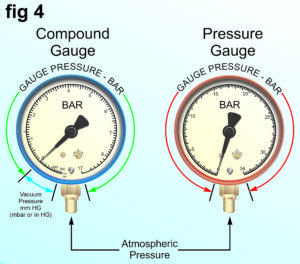

A conventional Pressure Gaugereads the positive pressure of a gas or liquid above Atmospheric Pressure. A Compound Gaugeis able to indicate both positive pressure and the negative pressure created by Vacuum Pressure.

FIGURE 4

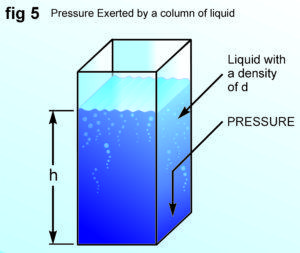

Pressure of a Column of Liquid

The pressure exerted by a column of liquid due to gravitational force is dependant upon the Densityof the liquid and the Heightof the column:

Pressure (kg/cm2) = Density (kg/m3) x Height (m)

FIGURE 5

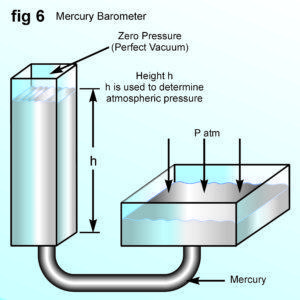

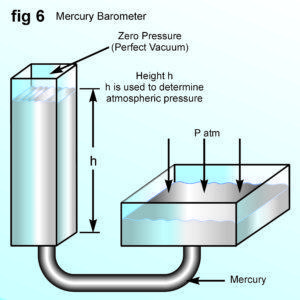

Measurement of Atmospheric Pressure

Atmospheric Pressurecan be measured using a Mercury Barometer. The Height(h) of the column of mercury (Hg) supported by Atmospheric Pressure allows a direct pressure reading to be obtained and is normally indicated as in. Hgor mm. Hg.

FIGURE 6

Work Power and Energy

Work is described as the product of a force exerted upon a body resulting in motion. This is expressed as follows:

Work (J) = Force (N) x Distance (m)

Example

A water chiller weighing 1000 kg is lifted from ground level to the roof of a building. The vertical distance is 15 metres. The force applied is exerted against gravity. Weight in kg must therefore be converted to Newtons:

Work (J) = Weight (1000 kg) x 9.807 N/kg x Distance (15 m). = 147105 J (147.105 kJ)

Power defines the rate at which Work is applied or absorbed. Power is determined by the following:

Work (J)

Power (J/s) = ———-

Time (s)

Using the previous example, if the chiller is lifted to the roof in 5 minutes (300 seconds) the Powerrequired will be:

Work (147105 J)

Power (J/s) = ——————– = 490.35J/s (Watts)

Time (300 s)

Energy is defined as the ability to perform Work. A body possesses energy when it has the capacity to perform Work. Energy is measured in Joules and takes a number of forms:

Kinetic Energy is the energy possessed by a body due to motion or velocity. Kinetic Energyis given by:

(m) x (v2)

ke = ————

2

Where:

ke = Kinetic Energy in Joules (J)

m = Mass (kg)

v = Velocity (m/s)

Potential Energy is the energy possessed by a body due to its position or configuration. The amount of Work done by a body when moving from a given position or configuration to a reference position or condition is the measure of the body’s Potential Energy and is given by:

pe = (m) x (g) x (d)

Where:

pe = Potential Energy in Joules (J)

m = Mass (kg)

g = local Force of Gravity (N/kg)

d = Distance above reference point (m)

Total External Energy is the total of Kinetic Energy and Potential Energy possessed by a body.

Conservation of Energy

The First Law of Thermodynamics basically states that the amount of energy in a thermodynamic system is constant and that none can be gained or lost unless it is converted from one form to another. Energytakes many forms including mechanical energy, electrical energy, chemical energy and heat energy. Energycannot therefore be destroyed and is simply transferred from one body to another or converted in form.

NEXT – Vol 2:

More basic theory including heat energy, temperature, properties of liquids, gases and gas processes.

ABOUT THE AUTHOR

Mike Creamer began his career in mechanical engineering spending several years in precision engineering and instrument workshops followed by engineering design. He then joined Rotaire Driers (now Munters) in the early seventies to design chemical dehumidifiers but soon moved on to handle all close temperature and humidity control applications engineering for the company. Extensive use of DX after-cooling in these systems aroused his interest in refrigeration and in 1977 he joined Dunham-Bush International as Chief Applications Engineer. Mike then moved on to become Technical Manager and Sales Manager with the Conder Group and Marketing Manager with BRD (Air Conditioning) Ltd. He then spent 3 years working on variable speed refrigeration and air conditioning systems in the UK and USA at General Manager, Quality Director and Managing Director level. Mike is now Managing Director of Business Edge Ltd and Advanced Refrigeration Technology Ltd and also a Senior Partner of A.C.E. (Advanced Consulting Engineers).

Mikes career spans 27 years in air conditioning and refrigeration covering product design, control systems, low temperature water chillers, cold storage, process cooling, low temperature compound refrigeration, supermarket refrigeration, bottling plants (ammonia), environmental chambers and variable speed refrigeration and air conditioning to over 2400 kW. Mike also runs the Air Conditioning and Refrigeration Technology and Refrigerant Safe Handling courses for Business Edge Ltd and is a member of the Quantum Suite Software Development Team.

For more details regarding Master Class, Training Courses, the latest F-Gas Training Manual and more, follow the url: www.businessedgeltd.co.uk