As a leading installer of HVAC/R systems, Danston Ltd faced a challenge when one of their largest fruit-producing clients needed an urgent refrigeration installation and upgrade. With hot weather approaching and a large quantity of produce due to be cooled, time was of the essence.

The project required recovering refrigerant from old systems that would be replaced. However, previous similar projects had resulted in slow recovery times caused by rising bottle temperatures and stubborn refrigerant sitting in cold evaporator coils at low levels in the facility.

The Solution: CPS Pro-Set® MT69 Molecular Transformator Sub Cooler

On meeting the Evomart team at the HRS Event, the Danston team was introduced to the MT69 Molecular Transformator Sub Cooler. The benefits were highlighted and the unit supplied.

Operating as a submersible condenser or evaporator, this innovative patent-pending technology is designed to boost recovery efficiency by swiftly transforming vapor refrigerant into liquid, saving both time and money with each use.

Designed to be compact and rugged, and requiring zero maintenance, it’s compatible with all major brands of refrigerant recovery equipment.

Setup and Results

Danston Ltd tested the effectiveness of the CPS Pro-Set® MT69 by conducting a recovery operation with the sub cooler, that they would compare with a previous benchmark operation with similar parameters.

Benchmark Operation

The benchmark recovery operation, to recover 9 kg of R448a, used the following setup and method, with no bottle cooling or bottle changing:

- System connected to gauges; gauges connected to the recovery unit and recovery unit connected to the recovery bottle on zeroed scales.

- Hoses were purged through of air.

- Recovery was started and continued until vacuum cut out of recovery unit.

Using this approach, the operation took 2.9 hours (173 minutes) to complete.

MT69 Test

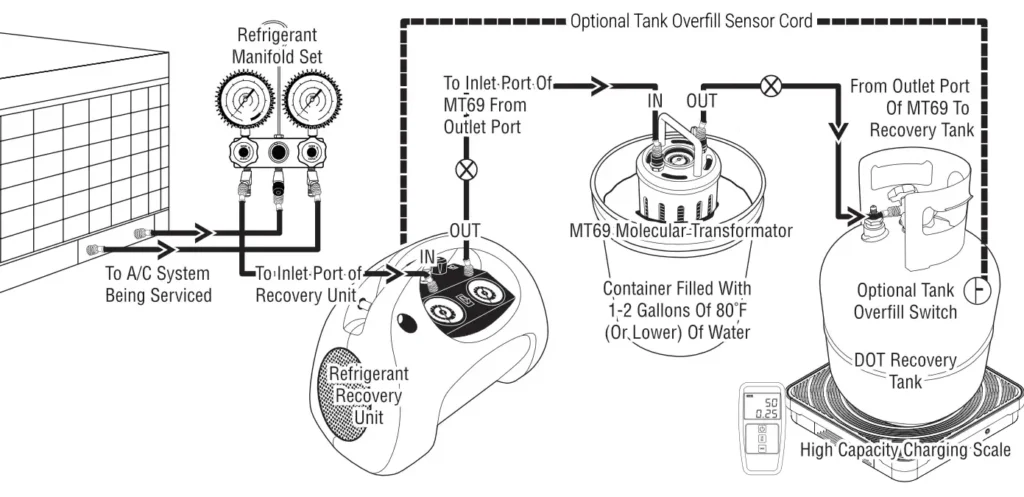

With similar parameters to the benchmark test, Danston Ltd conducted a recovery operation, this time incorporating the MT69 Molecular Transformator Sub Cooler, in accordance with product instructions. As with the benchmark operation, this test also required recovery of 9 kg of R448a refrigerant from a system, but using the following setup and method, with no bottle cooling or bottle changing:

- Hoses connected to MT69 and to vacuum pump.

- MT69 evacuated and hose valves shut.

- System connected to gauges; gauges connected to the recovery unit recovery; recovery unit connected to MT69 hoses, MT69 connected to bottle zeroed on scales.

- Hoses purged through of air.

- MT69 dropped into 14l bucket of water @ 12 °C.

- Recovery was started and continued until vacuum/LP cut out of recovery unit.

- Hose valves shut around MT69.

- MT69 connected to recovery unit and recovery unit connected to recovery bottle.

- Refrigerant recovered from MT69 until vacuum cut out.

The results were impressive. With the operation taking just 1.8 hours (107 minutes).

including the CPS Pro-Set® MT69 in the setup had delivered a 62% faster recovery speed, when compared to the benchmark operation conducted without the MT69.

Cumulative Time Savings

The significant reduction in recovery time offered by the CPS Pro-Set® MT69, while adding only 10 minutes to setup, allowed Danston Ltd to anticipate important cumulative time savings for larger projects of 50-120 kg, including the urgent upgrade for their fruit producer client.

Conclusion: Save Time and Money During Refrigerant Recovery

The successful implementation of the CPS Pro-Set® MT69 Molecular Transformator Sub Cooler, yielding significant time savings, highlights the benefits of using this technology. By embracing this innovation, HVAC/R professionals can streamline their operations, improve performance, and meet demanding deadlines.

This tangible difference to project timelines and efficiency, offered by the CPS Pro-Set® MT69, saves time and money with each use, making it an essential tool for any HVAC/R professional looking to optimise refrigerant recovery processes and boost their bottom line.

Our appreciation to Jason Moss of Danston Ltd. for the report on which this case study is based.